Phased Array UT Tethered Pig

PHASED ARRAY UT

TETHERED PIG

Crack Detection and Wall Loss for Well Integrity and Downhole Inspections

Crack Detection and Wall Loss Inspections for Well Integrity and Downhole Inspections

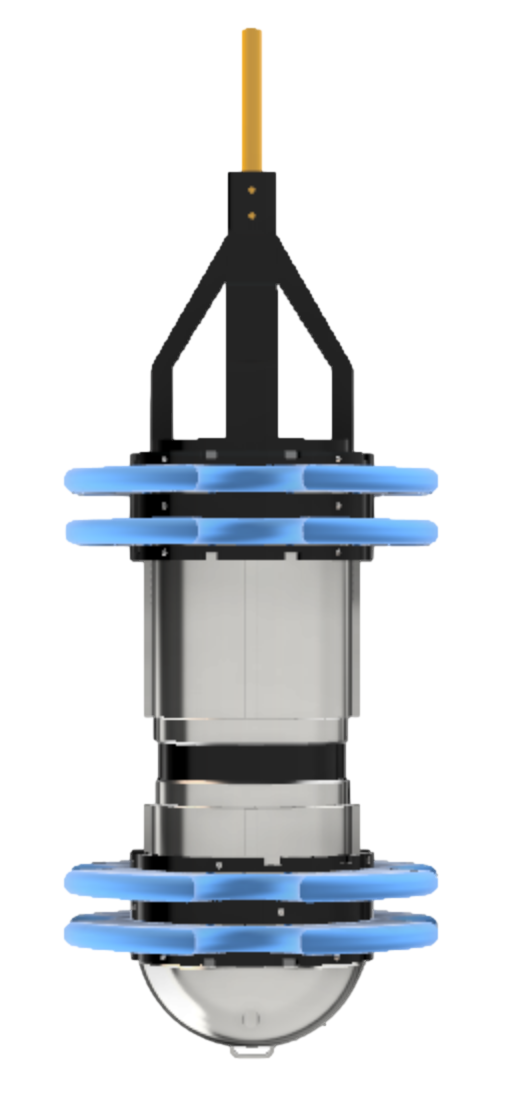

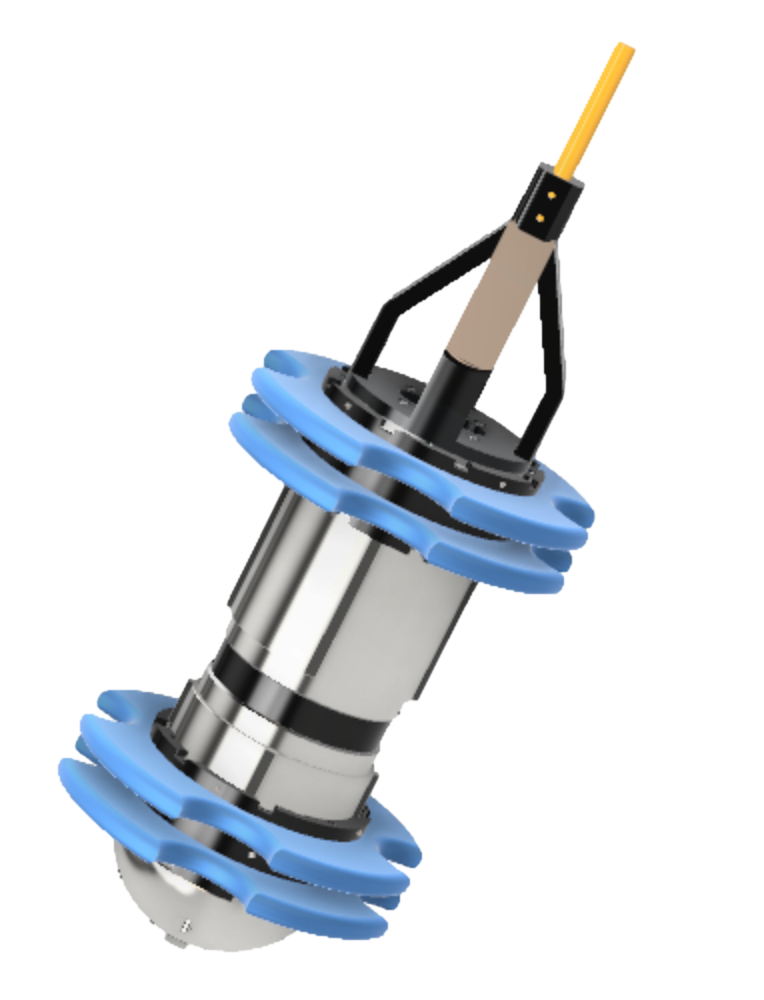

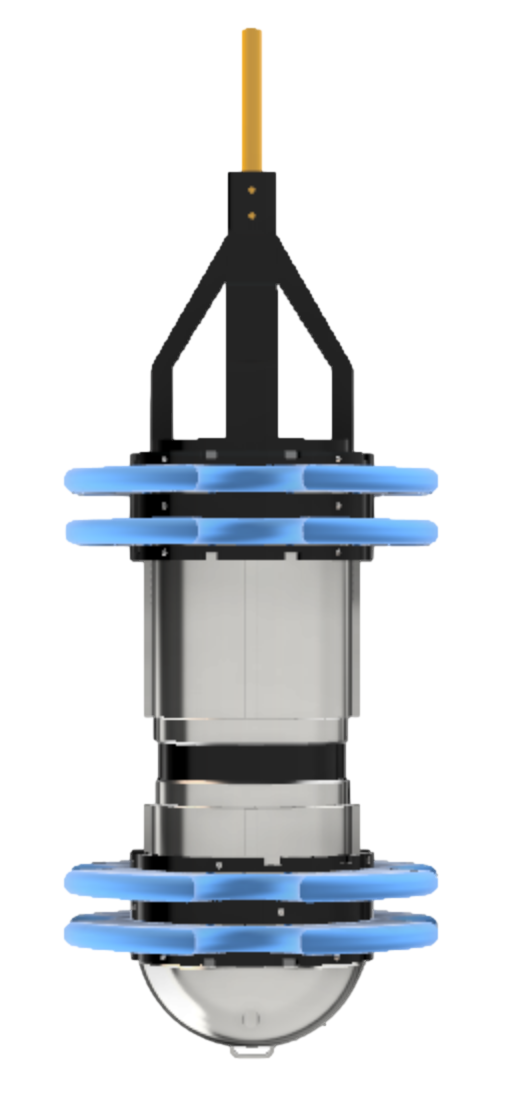

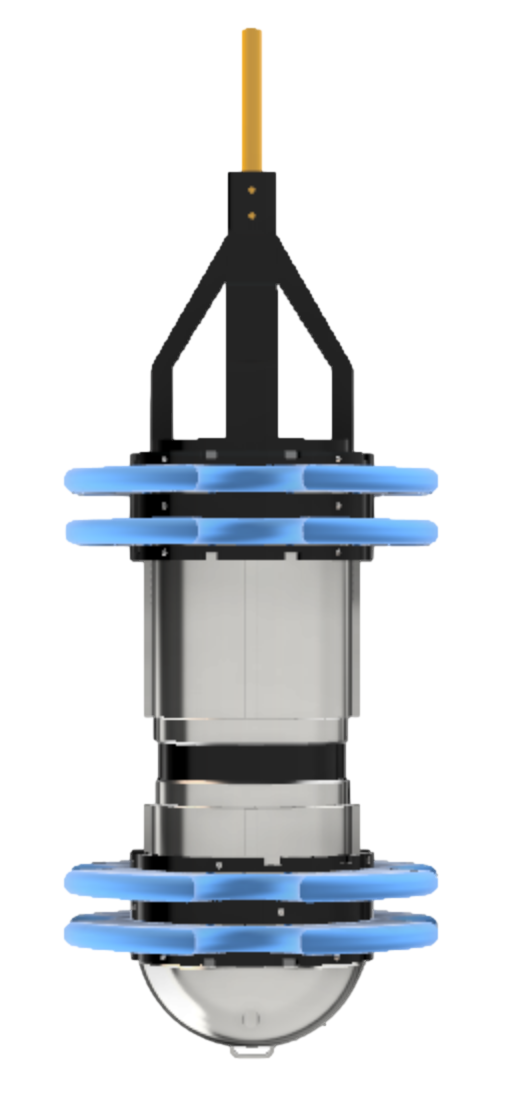

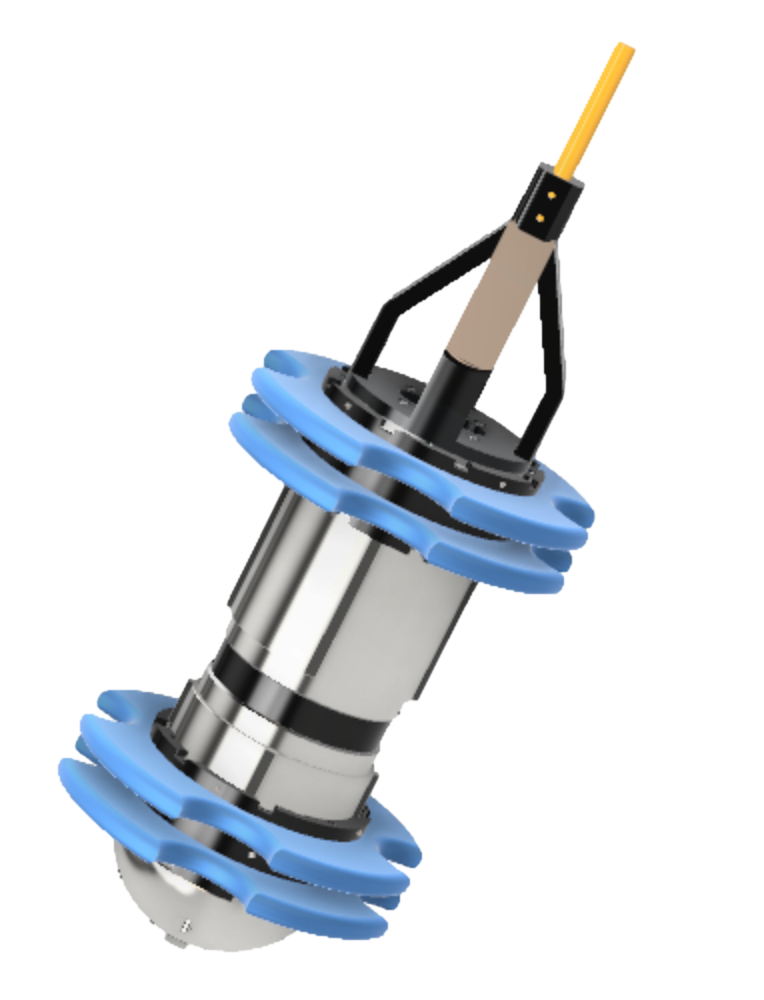

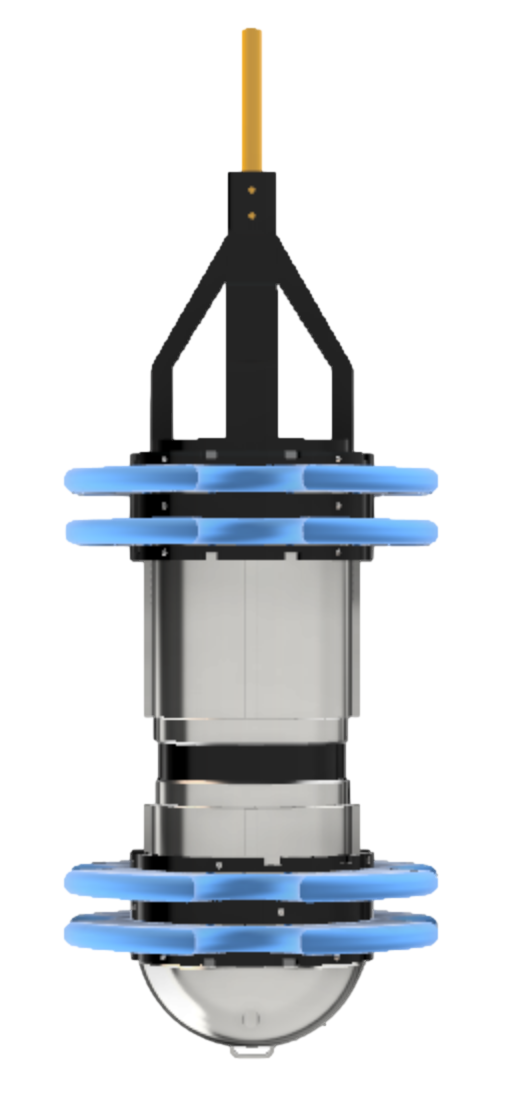

Vector Phased Array Tethered Pig is a tethered inspection tool with a 360 degree Circular Phased Array ultrasonic sensor designed for well integrity and downhole inspections of diameters ranging from 2inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss on these hard to reach filled pipes and tubes.

The tool is capable of being pushed into the pipe with a push rod or lowered in via a winch with a maximum 500m cable length. The Circular Phased Array sensors provide direct pipe thickness data for precision measurement of corrosion and anomalies. The Phased Array ultrasound sensor can send straight or angled beams into the material to scan for wall thickness, cracks and weld defects.

The onboard encoder ensures millimetre accuracy when scanning. The Bidirectional tool operation guarantees high density sampling rates for each application, ensuring 100% probability of detection of critical defects and extremely thin piping. 100% inspection coverage of wells, risers, casings, caverns, hydrants and fingers can now be performed with this tool.

Vector Phased Array Tethered Pig is a tethered inspection tool with a 360 degree Circular Phased Array ultrasonic sensor designed for well integrity and downhole inspections of diameters ranging from 2inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss on these hard to reach filled pipes and tubes.

The tool is capable of being pushed into the pipe with a push rod or lowered in via a winch with a maximum 500m cable length. The Circular Phased Array sensors provide direct pipe thickness data for precision measurement of corrosion and anomalies. The Phased Array ultrasound sensor can send straight or angled beams into the material to scan for wall thickness, cracks and weld defects.

The onboard encoder ensures millimetre accuracy when scanning. The Bidirectional tool operation guarantees high density sampling rates for each application, ensuring 100% probability of detection of critical defects and extremely thin piping. 100% inspection coverage of wells, risers, casings, caverns, hydrants and fingers can now be performed with this tool.

DETECTION CAPABILITIES

SYSTEM SET UP

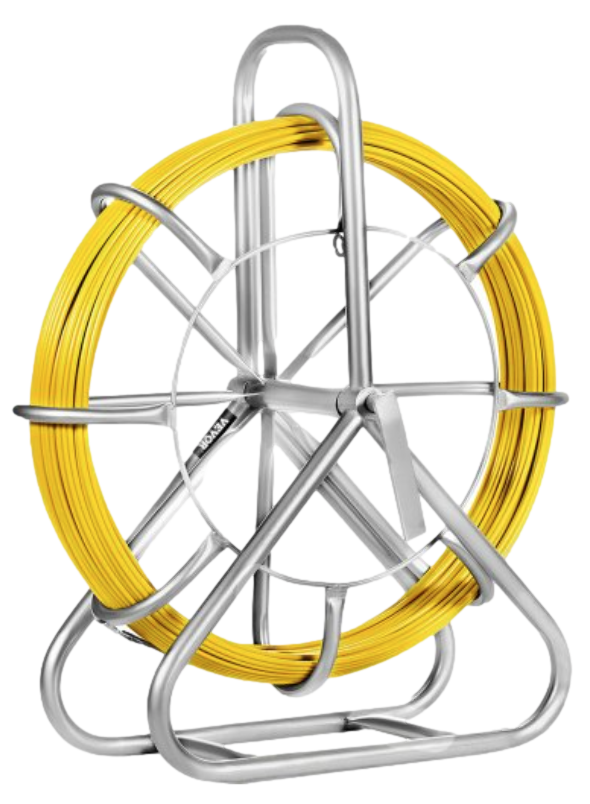

Vector tethered smart pig is made up of four main items. The tethered pig which can be customised to fit a specific diameter. A control unit with the inspection software to control the tethered pig. A push rod cable up to 500m in length and a lowering winch.

Tethered Pig

Control Unit with Inspection Software

Push Rod Cable

Lowering Winch

APPLICATIONS

Crack Detection and Wall Loss Inspections for Well Integrity and Downhole Inspections

Vector Phased Array Tethered Pig is a tethered inspection tool with a 360 degree Circular Phased Array ultrasonic sensor designed for well integrity and downhole inspections of diameters ranging from 2inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss on these hard to reach filled pipes and tubes.

The tool is capable of being pushed into the pipe with a push rod or lowered in via a winch with a maximum 500m cable length. The Circular Phased Array sensors provide direct pipe thickness data for precision measurement of corrosion and anomalies. The Phased Array ultrasound sensor can send straight or angled beams into the material to scan for wall thickness, cracks and weld defects.

The onboard encoder ensures millimetre accuracy when scanning. The Bidirectional tool operation guarantees high density sampling rates for each application, ensuring 100% probability of detection of critical defects and extremely thin piping. 100% inspection coverage of wells, risers, casings, caverns, hydrants and fingers can now be performed with this tool.

Well Integrity

Riser and Caisson Inspection

Drill Piping

Process Piping

Hydrant Inspection

APPLICATIONS

Well Integrity

Riser and Caisson Inspections

Drill Piping Inspection

Process Piping

Well Integrity and Downhole Crack Detection and Wall Loss Inspections Using Phased Array

SYSTEM SET UP

Vector tethered smart pig is made up of four main items. The tethered pig which can be customised to fit a specific diameter. A control unit with the inspection software to control the tethered pig. A push rod cable up to 500m in length and a lowering winch.

Vector Phased Array Tethered Pig is a tethered inspection tool with a 360 degree Circular Phased Array ultrasonic sensor designed for well integrity and downhole inspections of diameters ranging from 2inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss on these hard to reach filled pipes and tubes.

The tool is capable of being pushed into the pipe with a push rod or lowered in via a winch with a maximum 500m cable length. The Circular Phased Array sensors provide direct pipe thickness data for precision measurement of corrosion and anomalies. The Phased Array ultrasound sensor can send straight or angled beams into the material to scan for wall thickness, cracks and weld defects.

The onboard encoder ensures millimetre accuracy when scanning. The Bidirectional tool operation guarantees high density sampling rates for each application, ensuring 100% probability of detection of critical defects and extremely thin piping. 100% inspection coverage of wells, risers, casings, caverns, hydrants and fingers can now be performed with this tool.

DETECTION CAPABILITIES

SYSTEM SET UP

Control Unit with Inspection Software

Push Rod Cable

Vector tethered smart pig is made up of four main items. The tethered pig which can be customised to fit a specific diameter. A control unit with the inspection software to control the tethered pig. A push rod cable up to 500m in length and a lowering winch.

Lowering Winch

Tethered Pig

Tethered

Pig

Control Unit with Inspection Software

Push Rod

Cable

Lowering

Winch

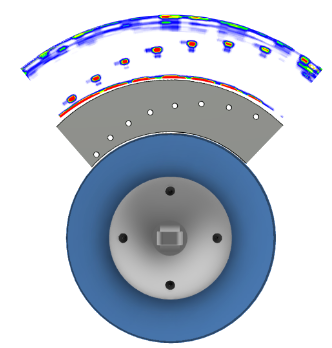

CIRCULARPHASED ARRAY TECHNOLOGY

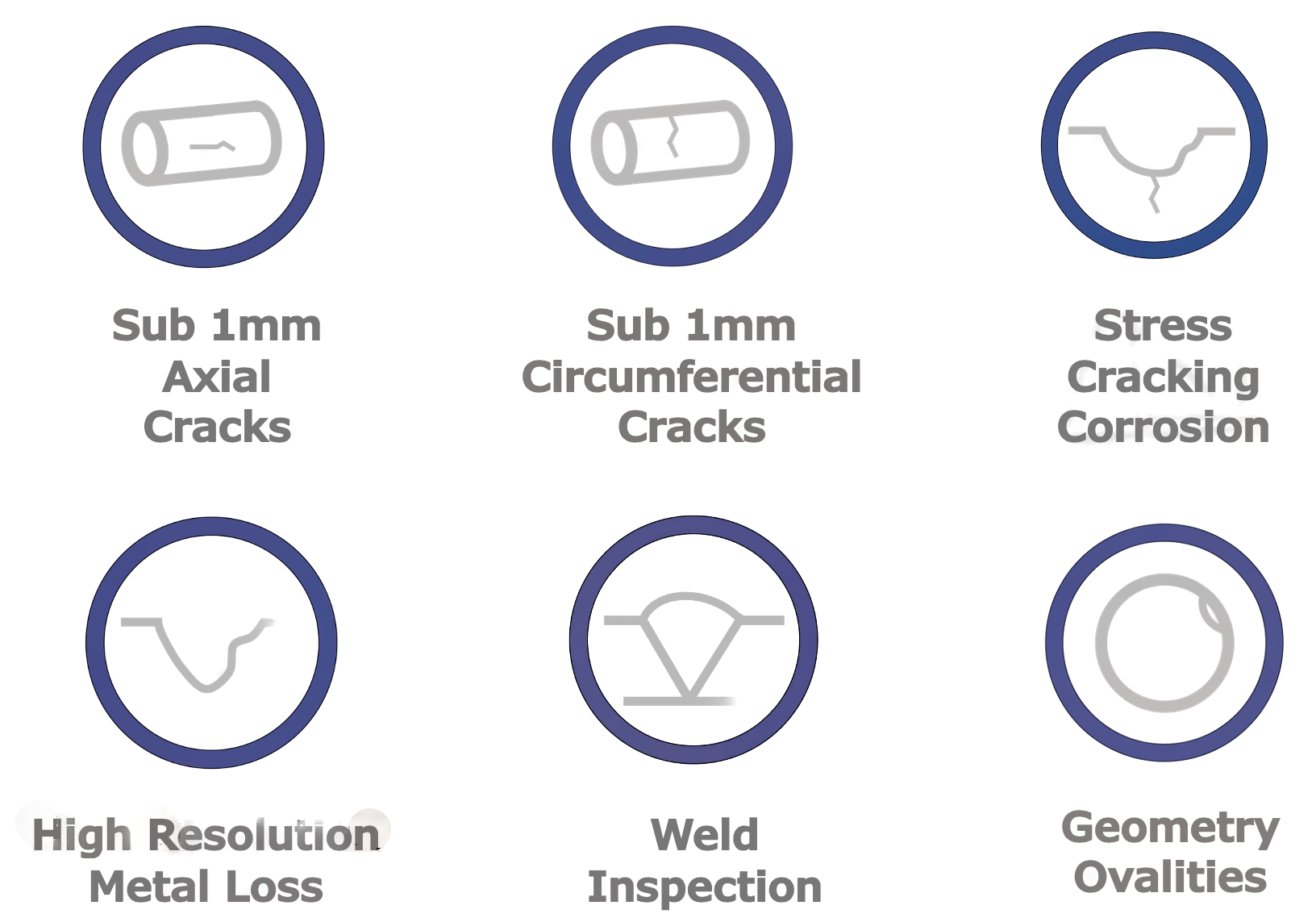

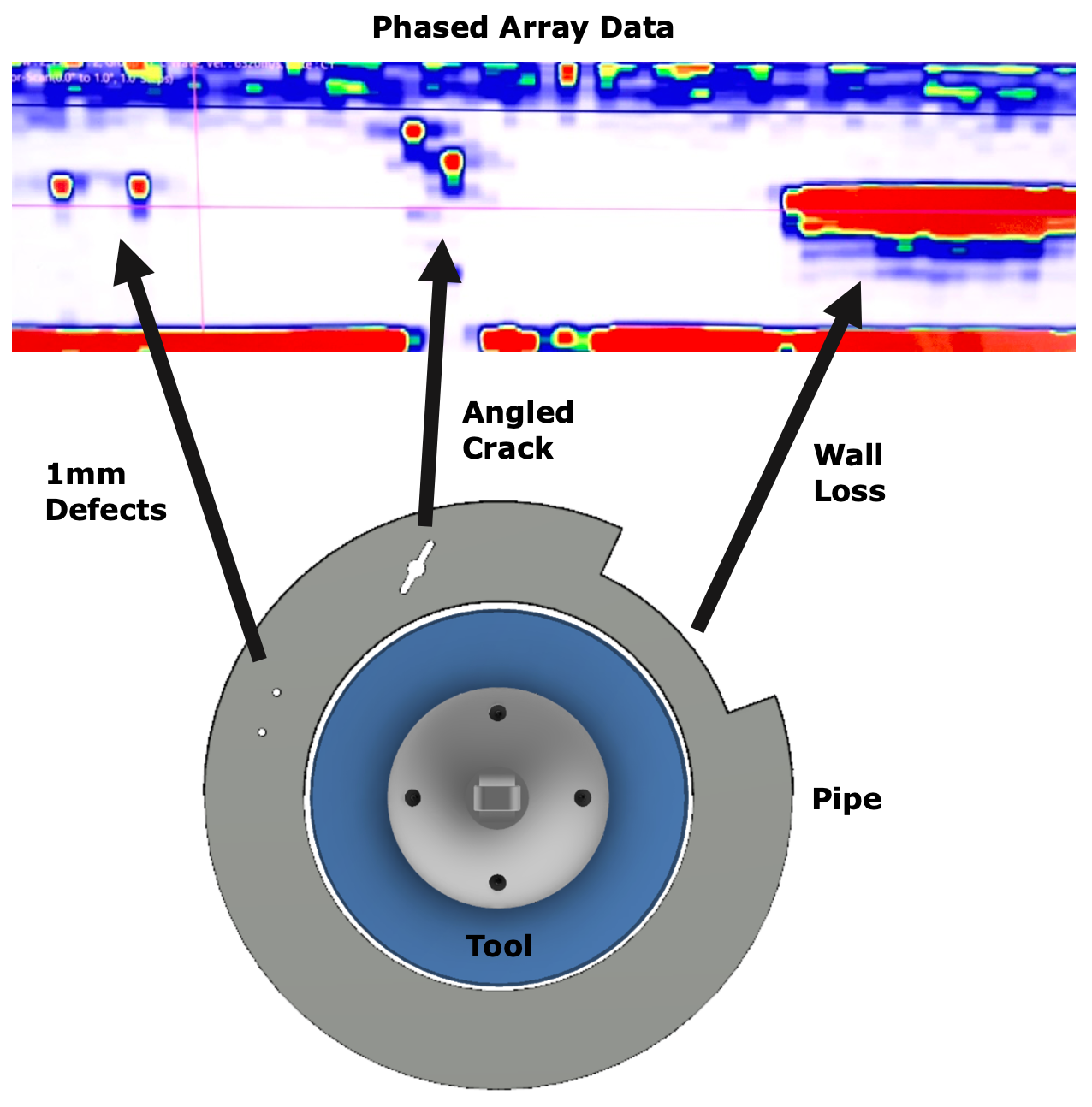

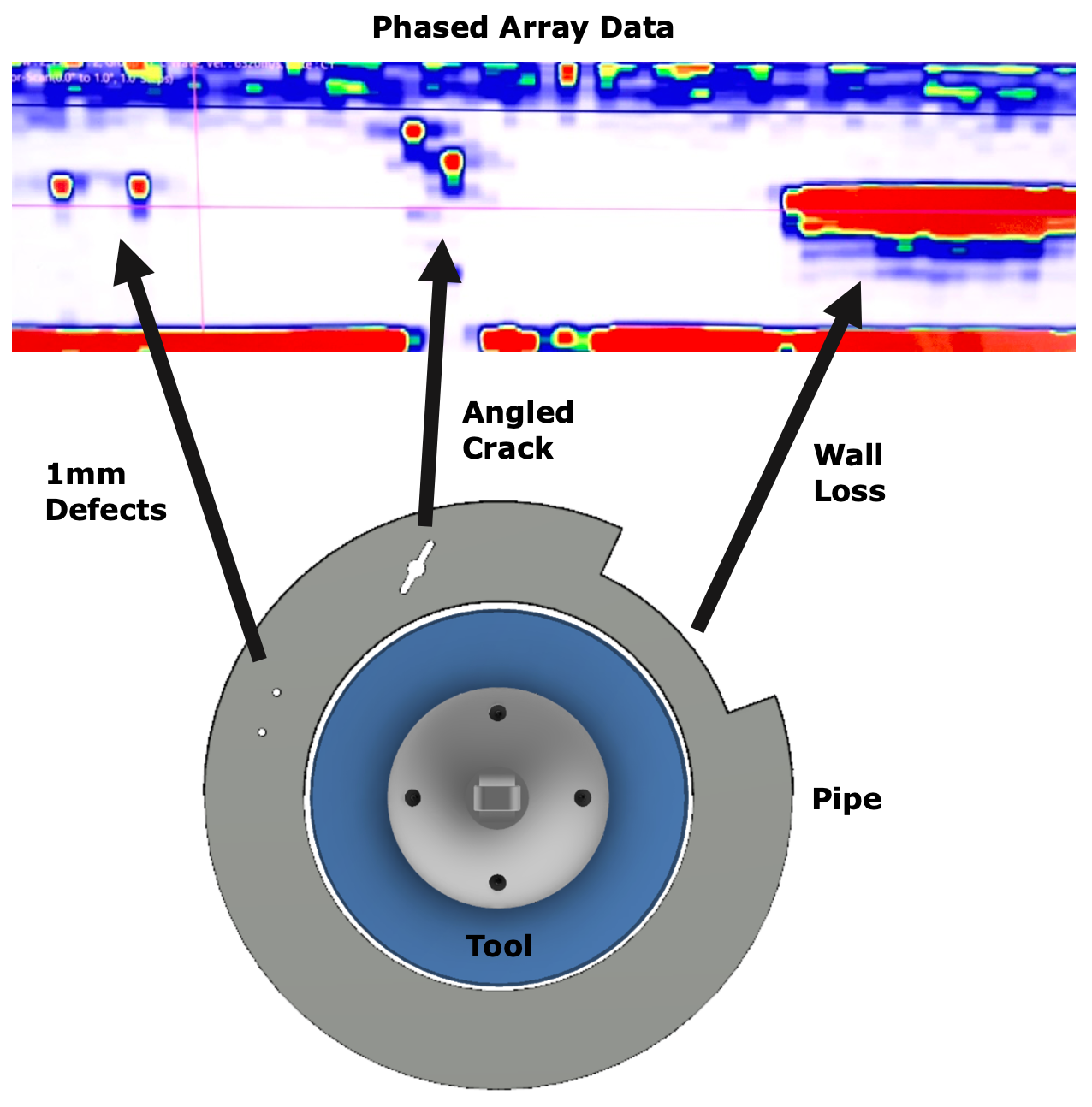

Circular Phased Array used high frequency ultrasound to send sound waves into the material in order to scan for defects and corrosion.

The unique Circular Phased Array sensor allows a combination of multiple angles and techniques to be fired into the pipe wall at the same time in one run improving the probability of detection and less downtime for operators.

The tool has the ability to detect and size for sub 1mm axial cracks, circumferential cracks, stress cracking corrosion (SCC), wall loss and geometry evaluation. The tool can also scan the pipeline welds at the same time.

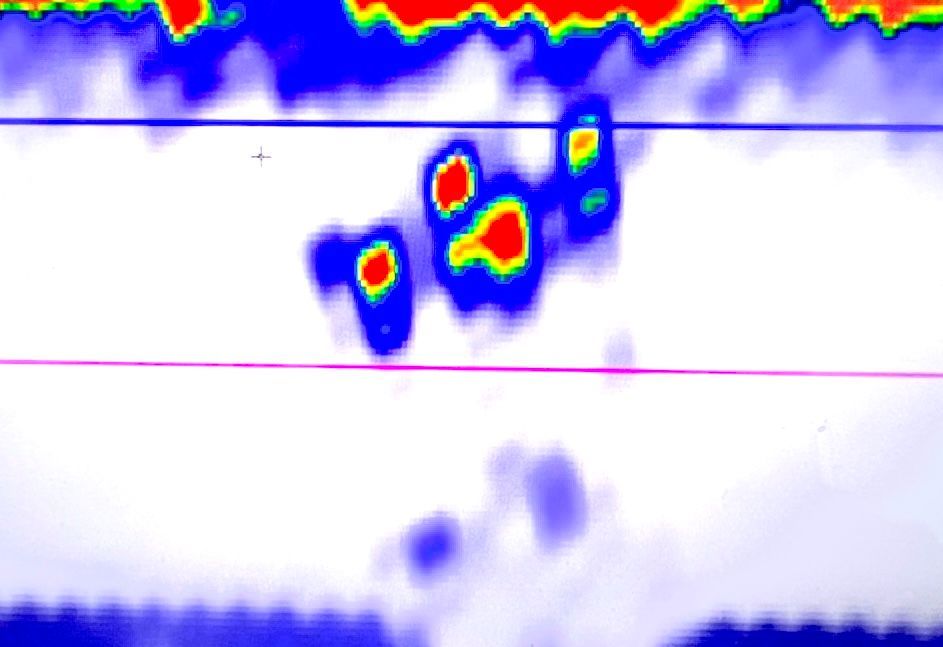

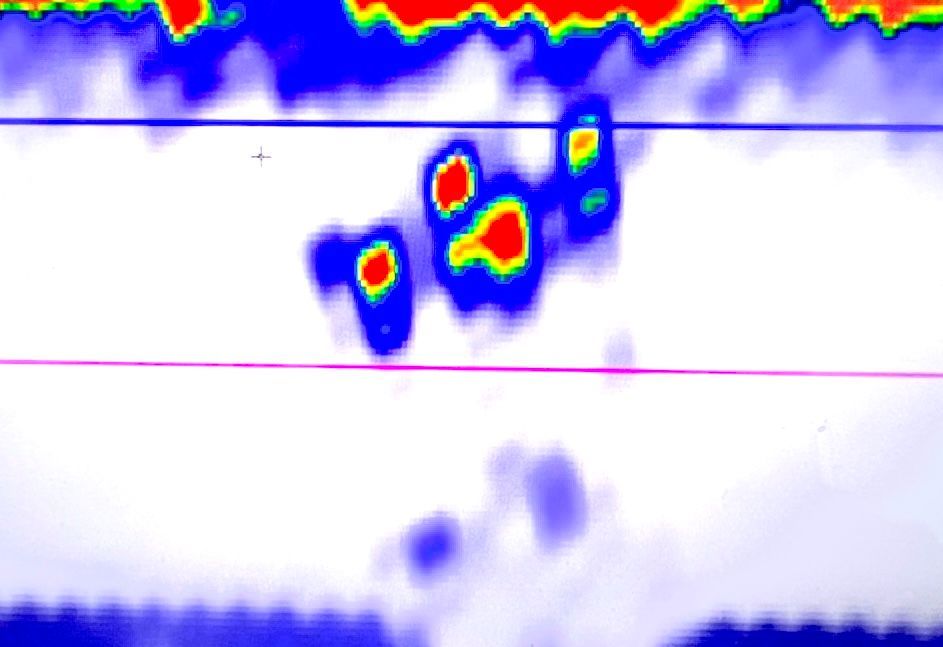

Phased Array Crack Data:

CIRCULAR PHASED ARRAYTECHNOLOGY

Circular Phased Array used high frequency ultrasound to send sound waves into the material in order to scan for defects and corrosion.

The unique Circular Phased Array sensor allows a combination of multiple angles and techniques to be fired into the pipe wall at the same time in one run improving the probability of detection and less downtime for operators.

The tool has the ability to detect and size for sub 1mm axial cracks, circumferential cracks, stress cracking corrosion (SCC), wall loss and geometry evaluation. The tool can also scan the pipeline welds at the same time.

CRACK DETECTION AND WALL LOSS INSPECTION CAPABILITIES

CRACK DETECTION ANDWALL LOSS INSPECTION CAPABILITIES

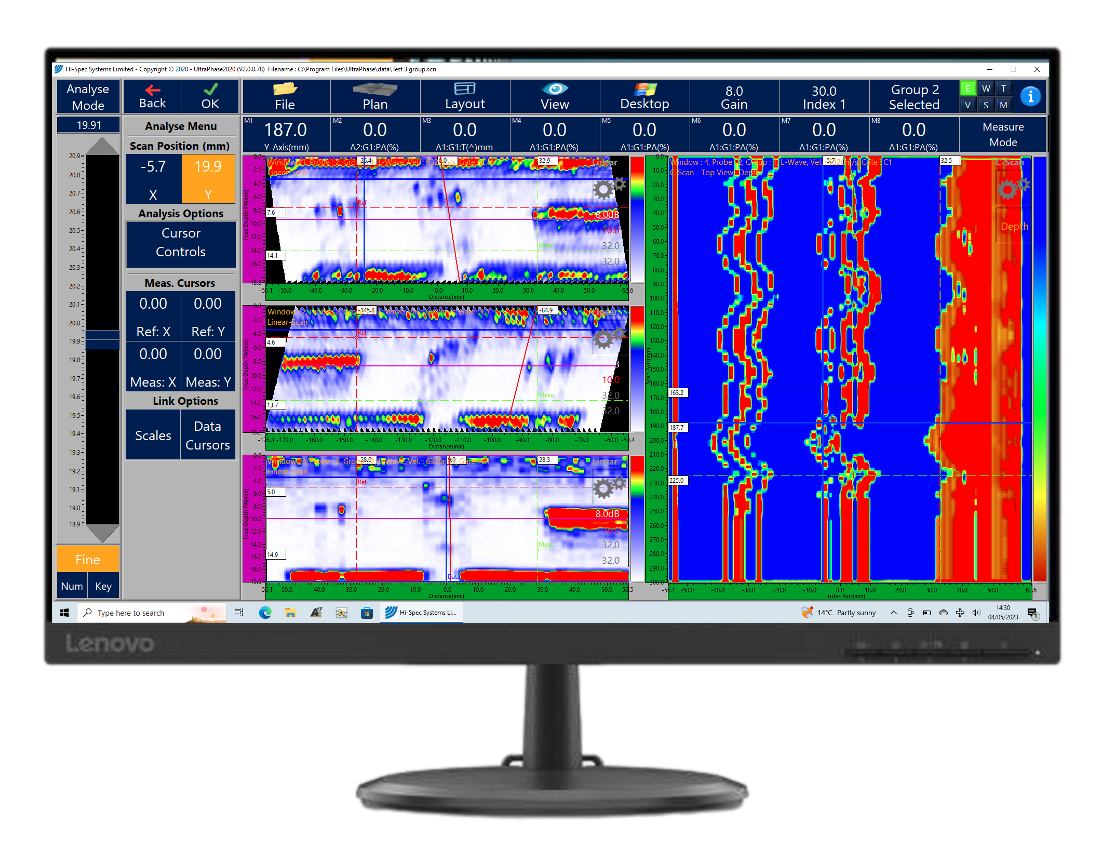

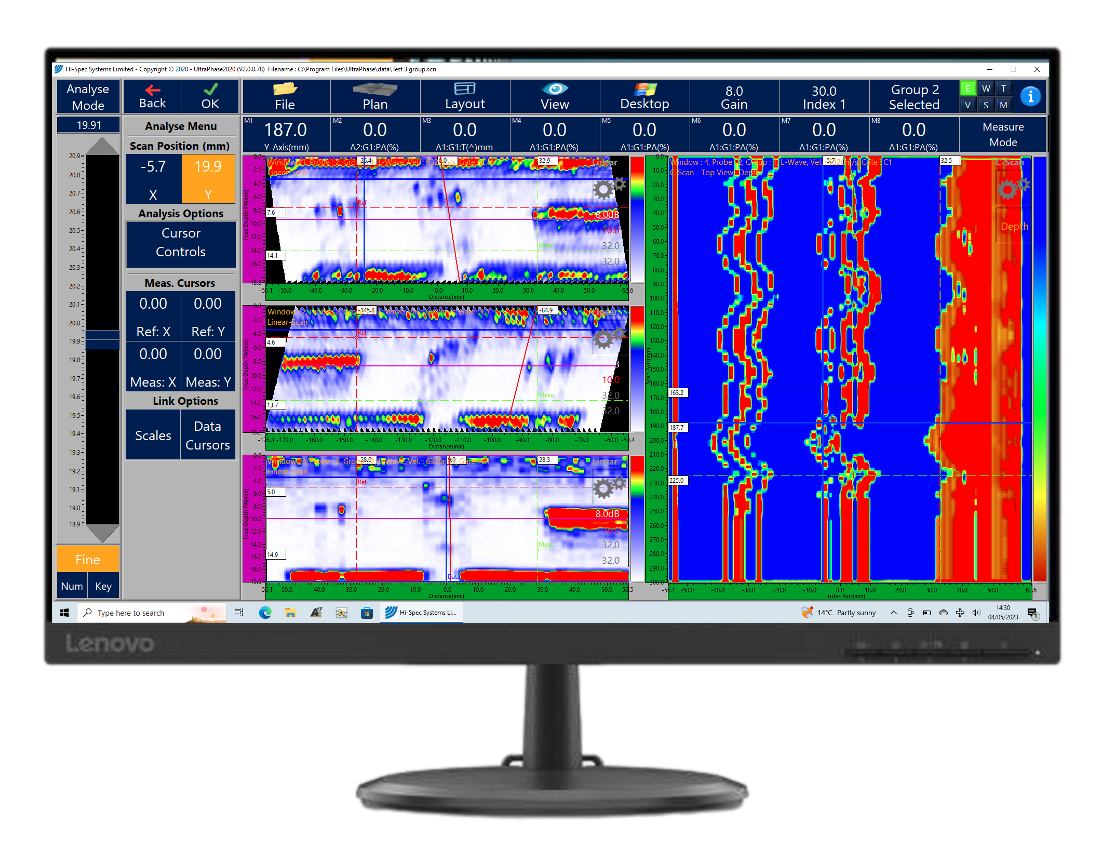

INSPECTION SOFTWARE

Vector Phased Array Smart Pig software is a powerful package capable of providing the operator the flexibility they need to set up the tool for many different applications. The powerful software package collects the raw A scan data in all orientations allowing for a higher probability of detection of defects and advanced analysis capabilities.

The package can perform multi group angled and zero degree inspection simultaneously. This makes sure no defect will be missed when scanning the pipe.

The software programs the tool for data acquisition in different mediums and sound velocities without the need for mechanical modification of the tool. The flexibility of optimising the configuration for specific applications ensures the best possible inspection outcome.

INSPECTION SOFTWARE

Vector Phased Array Smart Pig software is a powerful package capable of providing the operator the flexibility they need to set up the tool for many different applications. The powerful software package collects the raw A scan data in all orientations allowing for a higher probability of detection of defects and advanced analysis capabilities.

The package can perform multi group angled and zero degree inspection simultaneously. This makes sure no defect will be missed when scanning the pipe.

The software programs the tool for data acquisition in different mediums and sound velocities without the need for mechanical modification of the tool. The flexibility of optimising the configuration for specific applications ensures the best possible inspection outcome.

SPECIFICATIONS

Tether Length: Up to 500m Cable

(Longer available on request)

Inspection Time: Continuous

Max Tool Speed: Up to 0.3m/s

Max Tool Pressure: 100Bar

Temp Range: 0 to 65 degree

Wall Thickness: 1mm-100mm

Pipe Coverage: 100%

Tool Size Available: 2” – 12”

Applications: Riser, Well, Tubing, Casings, Caverns, Hydrants

UT Technique: Phased Array Corrosion Detection, Phased Crack Detection

Channels: 128 Channels with an aperture up to 32

Sensor Pitch: Configurable to Ring Size

Medium: Filled Liquid

Storage: Up to 8TB

SPECIFICATIONS

Tether Length: Up to 500m Cable (further available on request)

Inspection Time: Continuous

Max Tool Speed: Up to 0.3m/s

Max Tool Pressure: 100Bar

Temp Range: 0 to 65 degree

Wall Thickness: 1mm-100mm

Pipe Coverage: 100%

Tool Size Available: 2” – 12”

Applications: Riser, Well, Tubing, Casings, Caverns, Hydrants

UT Technique: Phased Array Corrosion Detection, Phased Crack Detection

Channels: 128 Channels with an aperture up to 32

Sensor Pitch: Configurable to Ring Size

Medium: Filled Liquid

Storage: Up to 8TB