Phased Array UT

In-Line Inspection Services

Combined Crack Detection

and Wall Loss Smart Pigging Technology

We are a global inspection technology company who specialise in providing crack detection and wall loss in-line inspection services using our circular Phased Array UT inspection technology.

We are a global inspection technology company who specialise in providing crack detection and wall loss in-line inspection services using our circular Phased Array UT inspection technology.

SERVICES

In-line inspection smart pigging services focusing on the challenging and unpiggable pipelines, process piping and furnace applications.

Pipeline Inspection

Unpiggable pipeline inspection services focusing on challenging pipelines with small diameters

(3" - 12") with tight back to back 1D bends and tubes.

Process Piping Inspection

Smart pigging inspection services for plant and process piping inspections focusing on small and difficult tubing and pipes.

Well and Downhole Inspection

Tethered smart pigging inspection services to scan for wall loss, crack detection and weld inspection on wells and downhole applications.

Fuel Loading Line Inspection

Intelligent pigging inspection services for fuel and marine loading lines using combined wall loss and crack detection smart pigging tools.

SEND US YOUR ENQUIRY:

Contact Form:

We will get back to you as soon as possible.

Please try again later.

PHASED ARRAY SMART PIG

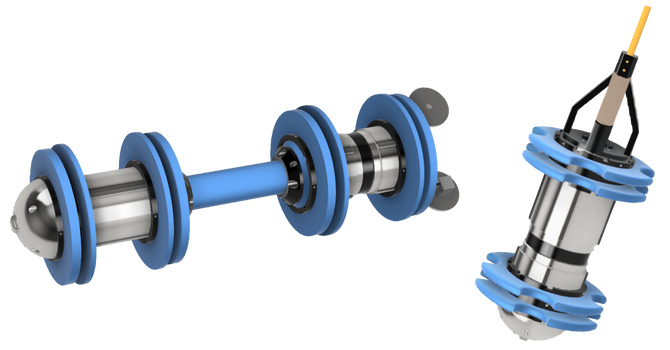

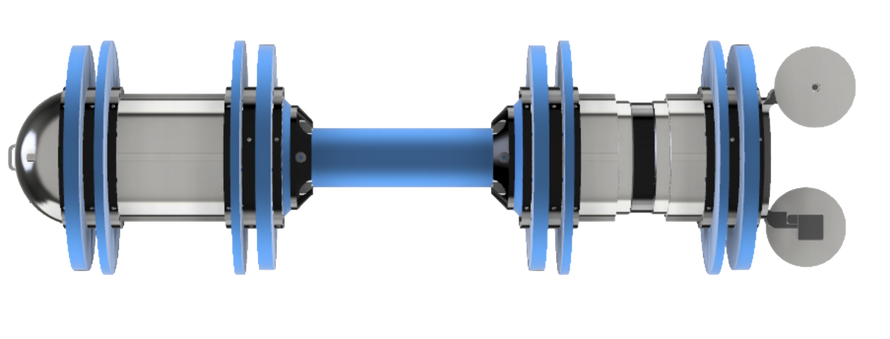

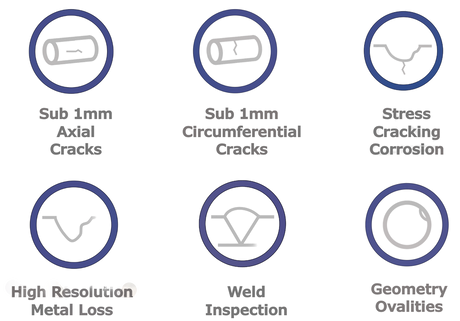

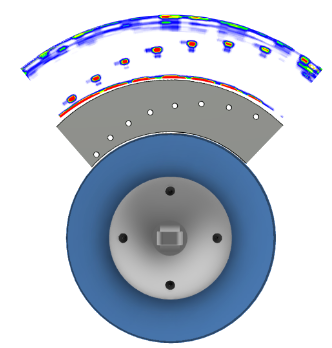

Vector Phased Array Smart Pig is a highly configurable free swimming smart pigging inspection tool with a circular Phased Array ultrasonic sensor. The unique sensor provides 100% coverage and fires a combination of multiple angles and techniques into the pipe wall at the same time in one run improving the probability of detection cracks and defects and less downtime for operators.

The modular tool is capable of adding additional battery and storage pods when needed for the those challenging long run inspections. The tool can be configured in a way to be bi-directional and pass through 1D bends for the tight space small run inspections.

Vector Phased Array Smart Pig is a highly configurable free swimming smart pigging inspection tool with a circular Phased Array ultrasonic sensor. The unique sensor provides 100% coverage and fires a combination of multiple angles and techniques into the pipe wall at the same time in one run improving the probability of detection cracks and defects and less downtime for operators.

The modular tool is capable of adding additional battery and storage pods when needed for the those challenging long run inspections. The tool can be configured in a way to be bi-directional and pass through 1D bends for the tight space small run inspections.

The dual encoders on board the tool make sure the data is collected with millimetre accuracy. The tool can run autonomously or tethered to tackle a range of applications.

PHASED ARRAY TETHERED PIG

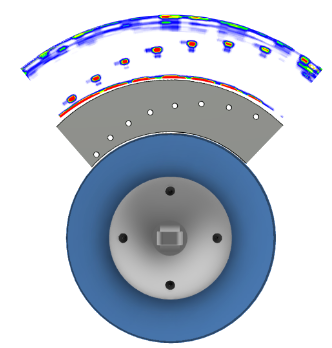

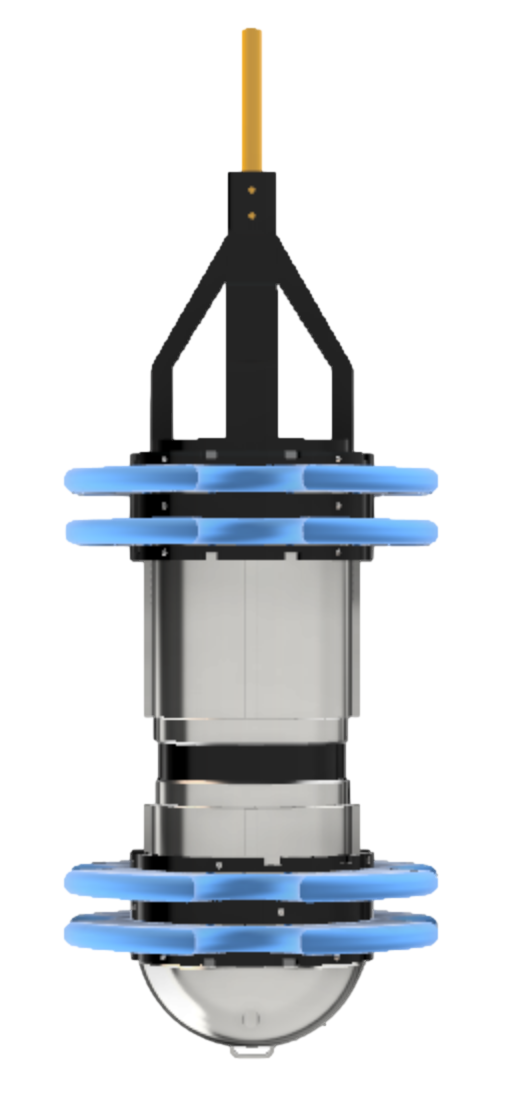

Vector Phased Array Tethered Pig is a tethered inspection tool with a 360 degree Circular Phased Array ultrasonic sensor designed for well integrity and downhole inspections of diameters ranging from 2inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss on these hard to reach filled pipes and tubes.

The tool is capable of being pushed into the pipe with a push rod or lowered in via a winch with a maximum 500m cable length. The circular Phased Array ultrasound sensor can send straight or angled beams into the material to scan for wall thickness, cracks and weld defects. 100% inspection coverage of wells, risers, casings, caverns, hydrants and fingers can now be performed with this tool.

Vector Phased Array Tethered Pig is a tethered inspection tool with a 360 degree Circular Phased Array ultrasonic sensor designed for well integrity and downhole inspections of diameters ranging from 2inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss on these hard to reach filled pipes and tubes.

The tool is capable of being pushed into the pipe with a push rod or lowered in via a winch with a maximum 500m cable length. The Circular Phased Array sensors provide direct pipe thickness data for precision measurement of corrosion and anomalies. The Phased Array ultrasound sensor can send straight or angled beams into the material to scan for wall thickness, cracks and weld defects.

The onboard encoder ensures millimetre accuracy when scanning. The Bidirectional tool operation guarantees high density sampling rates for each application, ensuring 100% probability of detection of critical defects and extremely thin piping. 100% inspection coverage of wells, risers, casings, caverns, hydrants and fingers can now be performed with this tool.

BLOG

INDUSTRIES

Pipelines

Refinery

Subsea

Furnace and Fired Heaters

KEEP IN TOUCH

Sign up and stay up-to-date about what's happening at Vector Inspection

We will get back to you as soon as possible

Please try again later