PHASED ARRAY UT

SMART PIG

CRACK DETECTION AND WALL LOSS FOR CHALLENGING INLINE PIPELINE INSPECTIONS

CRACK DETECTION ANDWALL LOSS FOR CHALLENGING PIPELINE INSPECTIONS

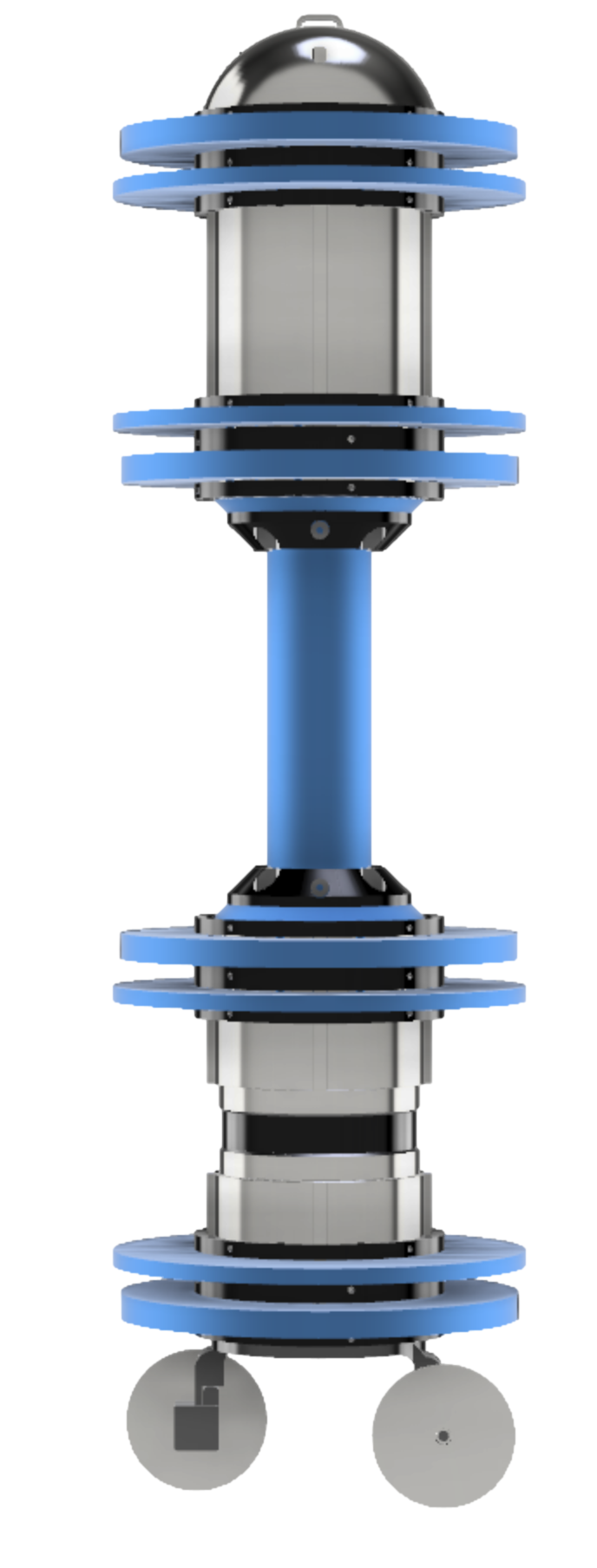

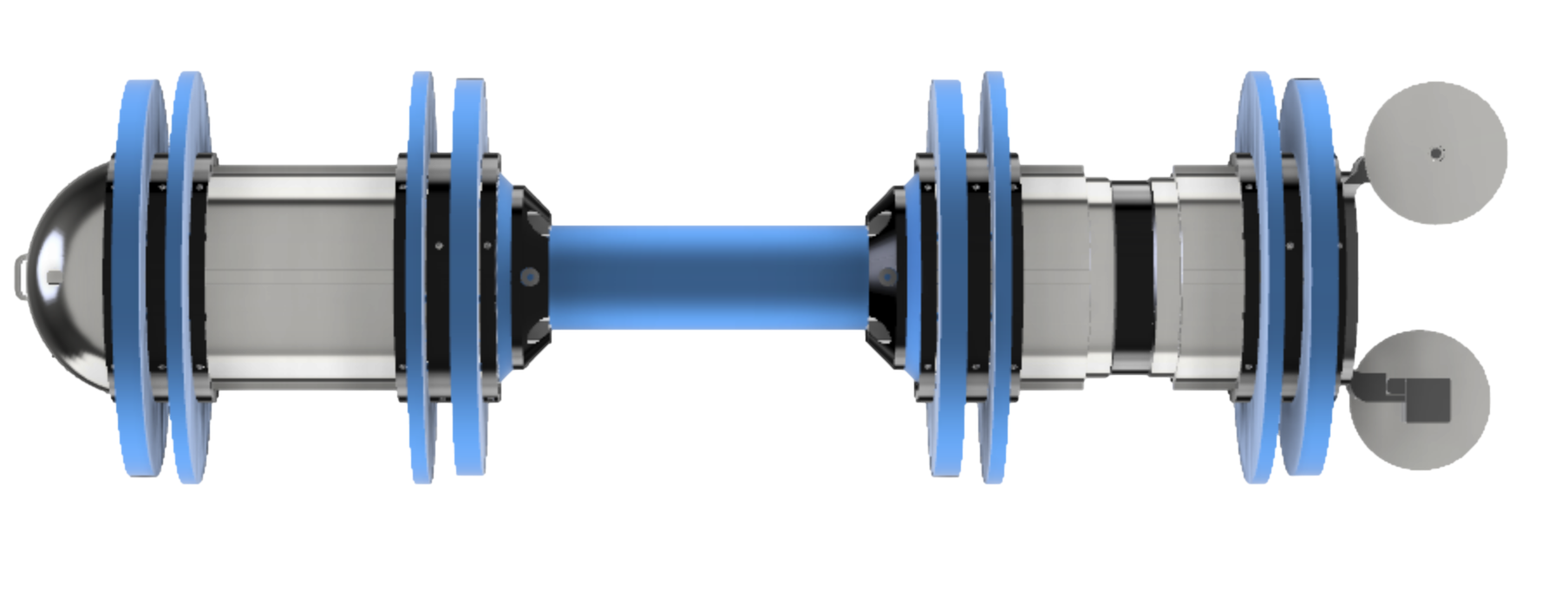

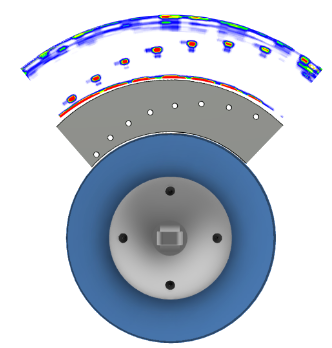

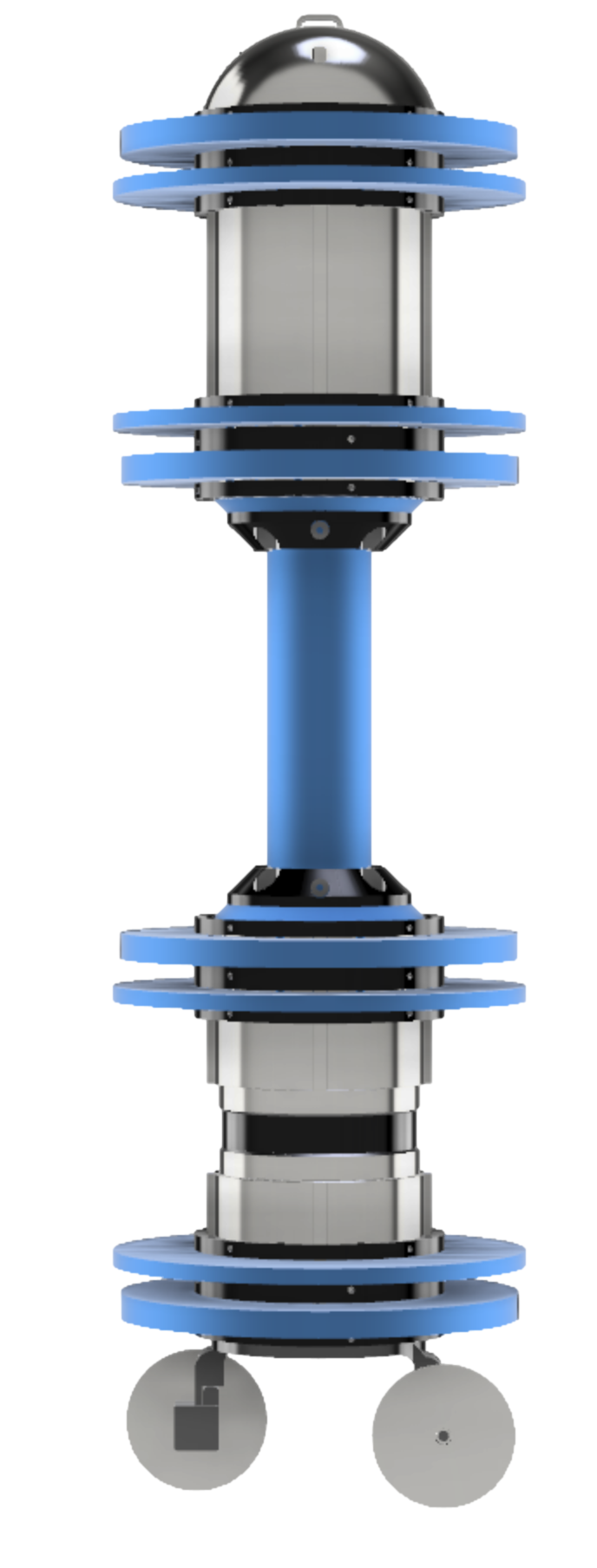

Vector Phased Array Smart Pig is a highly configurable NDT inspection tool with a Circular Phased Array ultrasonic sensor designed for unpiggable pipeline inspection of diameters ranging from 3inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss in one run.

The modular tool is capable of adding additional battery and storage pods when needed for the those challenging long run inspections. The tool can be configured in a way to be bi-directional and pass through 1D bends for the tight space small run inspections.

The dual encoders on board the tool make sure the data collected with millimetre accuracy. The tool can run autonomously or tethered to tackle a range of applications.

Fitness For Service (FFS) reports are available when using this tool including API 579 and POF 2016.

Vector Phased Array Smart Pig is a highly configurable NDT inspection tool with a Circular Phased Array ultrasonic sensor designed for challenging and unpiggable pipeline inspection of diameters ranging from 3inch to 12inch. The tool is designed to perform simultaneous crack detection and high resolution wall loss in one run.

The modular tool is capable of adding additional battery and storage pods when needed for the those challenging long run inspections. The tool can be configured in a way to be bi-directional and pass through 1D bends for the tight space small run inspections.

The dual encoders on board the tool make sure the data collected with millimetre accuracy. The tool can run autonomously or tethered to tackle a range of applications.

Fitness For Service (FFS) reports are available when using this tool including API 579 and POF 2016.

APPLICATIONS

APPLICATIONS

3inch to 12inch Pipelines

Furnace and Heaters

Subsea Pipelines

Refinery Piping

Marine Loading Lines

Power Generation Piping

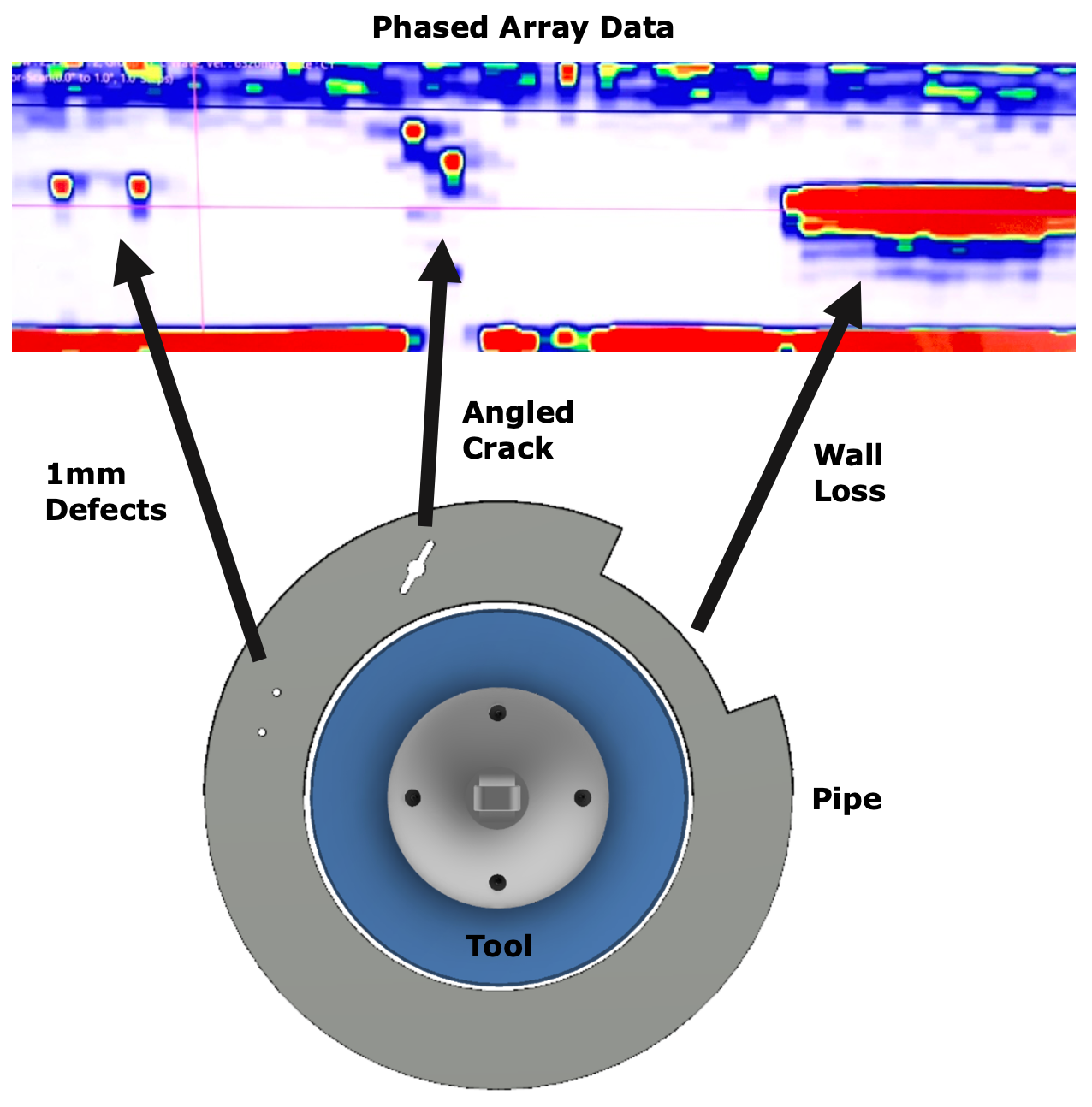

CIRCULARPHASED ARRAY CRACK DETECTION TECHNOLOGY

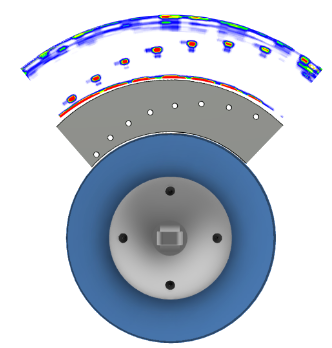

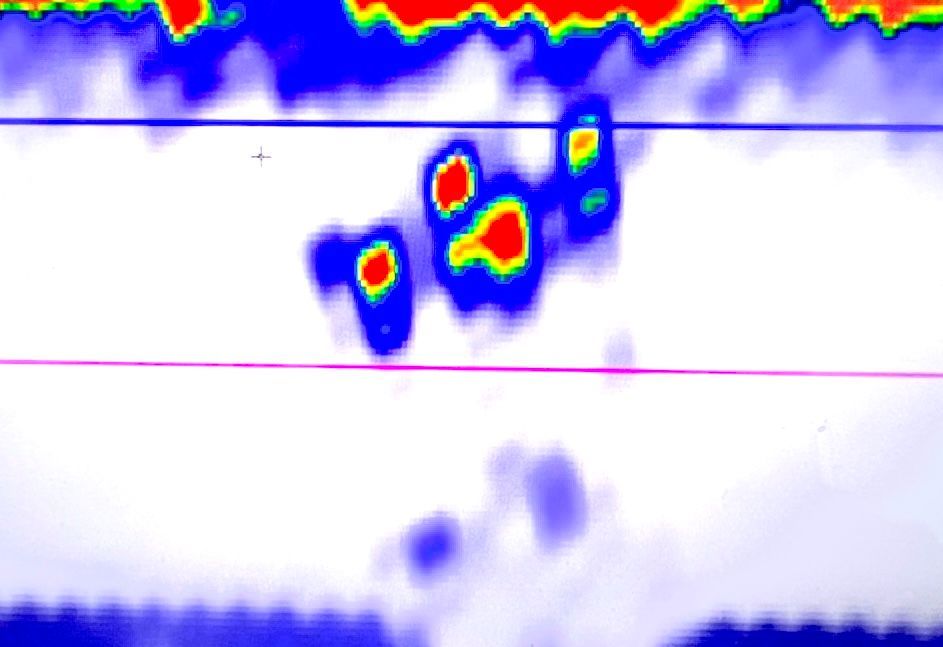

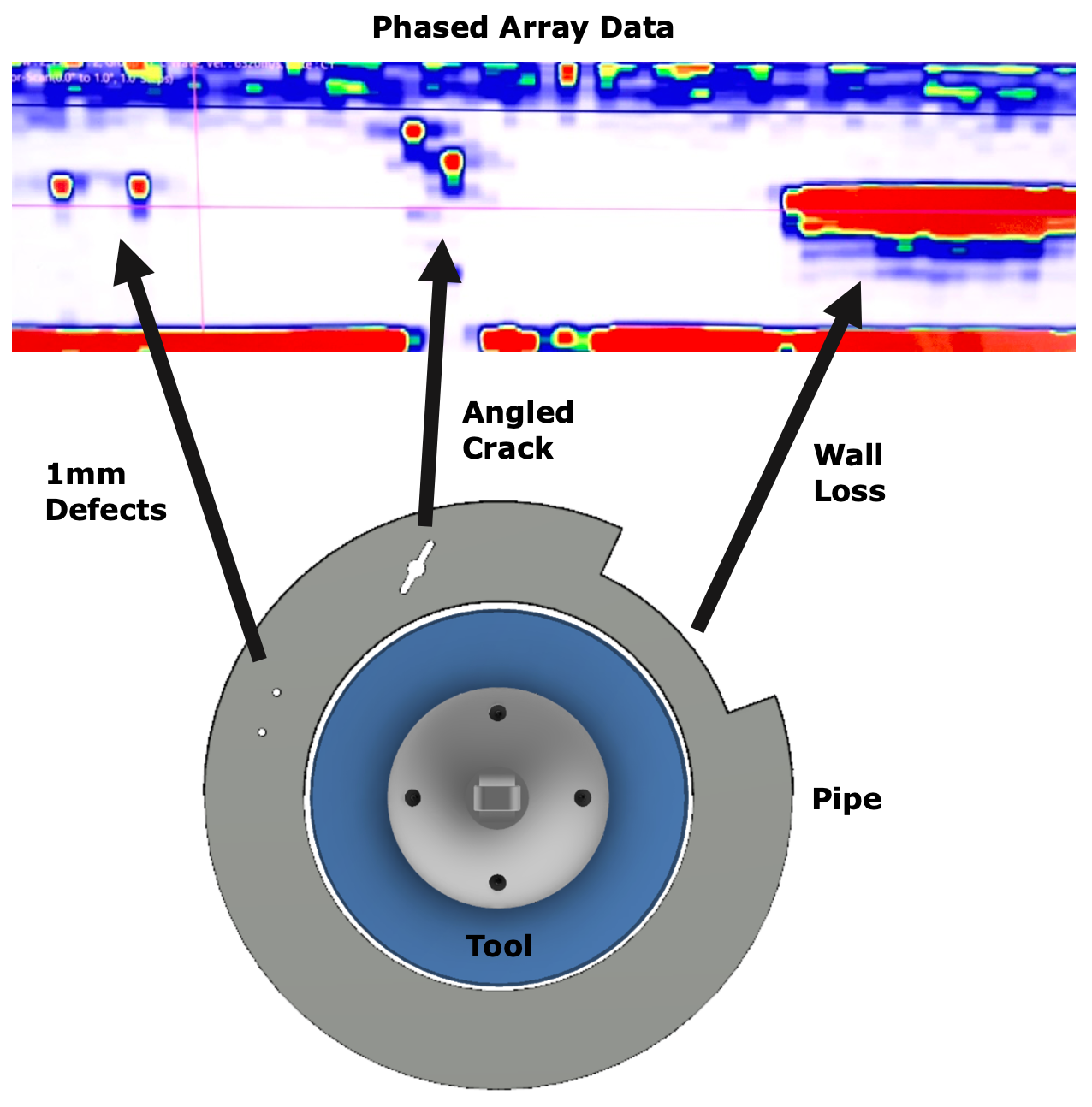

Circular Phased Array used high frequency ultrasound to send sound waves into the material in order to scan for defects and corrosion.

The unique Circular Phased Array sensor allows a combination of multiple angles and techniques to be fired into the pipe wall at the same time in one run improving the probability of detection and less downtime for operators.

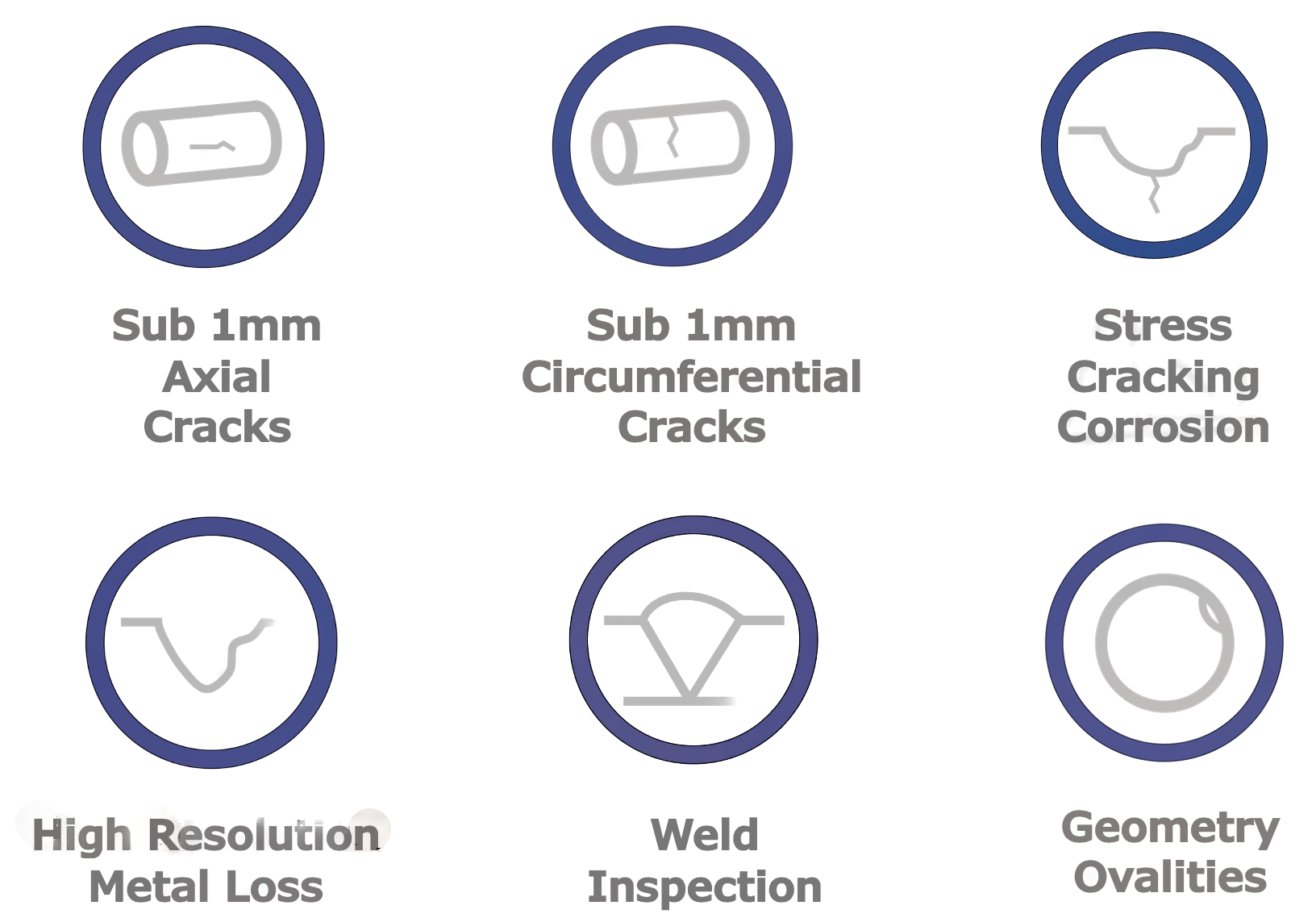

The tool has the ability to detect and size for sub 1mm axial cracks, circumferential cracks, stress cracking corrosion (SCC), wall loss and geometry evaluation. The tool can also scan the pipeline welds at the same time.

Phased Array Crack Data:

CIRCULAR PHASED ARRAYCRACK DETECTION TECHNOLOGY

Circular Phased Array used high frequency ultrasound to send sound waves into the material in order to scan for defects and corrosion.

The unique Circular Phased Array sensor allows a combination of multiple angles and techniques to be fired into the pipe wall at the same time in one run improving the probability of detection and less downtime for operators.

The tool has the ability to detect and size for sub 1mm axial cracks, circumferential cracks, stress cracking corrosion (SCC), wall loss and geometry evaluation. The tool can also scan the pipeline welds at the same time.

CRACK DETECTION AND WALL LOSS INSPECTION CAPABILITIES

CRACK DETECTION ANDWALL LOSS INSPECTION CAPABILITIES

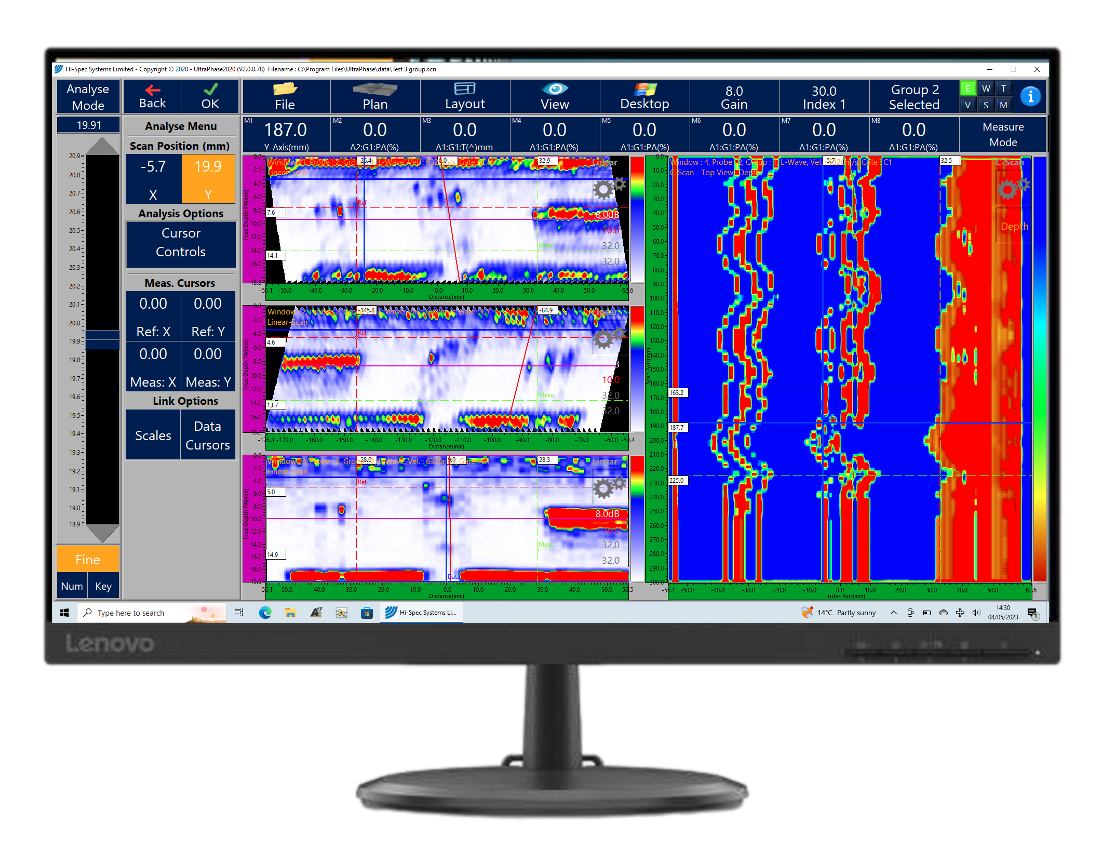

INSPECTION SOFTWARE

Vector Phased Array Smart Pig software is a powerful package capable of providing the operator the flexibility they need to set up the tool for many different applications. The powerful software package collects the raw A scan data in all orientations allowing for a higher probability of detection of defects and advanced analysis capabilities.

The package can perform multi group angled and zero degree inspection simultaneously. This makes sure no defect will be missed when scanning the pipe.

The software programs the tool for data acquisition in different mediums and sound velocities without the need for mechanical modification of the tool. The flexibility of optimising the configuration for specific applications ensures the best possible inspection outcome.

INSPECTION SOFTWARE

Vector Phased Array Smart Pig software is a powerful package capable of providing the operator the flexibility they need to set up the tool for many different applications. The powerful software package collects the raw A scan data in all orientations allowing for a higher probability of detection of defects and advanced analysis capabilities.

The package can perform multi group angled and zero degree inspection simultaneously. This makes sure no defect will be missed when scanning the pipe.

The software programs the tool for data acquisition in different mediums and sound velocities without the need for mechanical modification of the tool. The flexibility of optimising the configuration for specific applications ensures the best possible inspection outcome.

SPECIFICATIONS

Inspection Length: Up to 200km

Inspection Time: 200 Hours

Pipe Coverage: 100%

Capability: ID and OD Wall Loss

Max Tool Speed: Up to 2.0m/s

Max Tool Pressure: 100Bar

Temp Range: 0 to 65 degree

Wall Thickness: 2mm-25mm

Tool Size Available: 3” – 12”

Applications: Onshore and Offshore

UT Technique: Phased Array

Channels: 128 Channels with an aperture up to 32

Sensor Pitch: Configurable to Ring Size

PU Discs or Brushes Available

Data Saving: Raw A Scan

Storage: 8TB or Greater

IMU: Available

Tool Type: Autonomous and Tethered

SPECIFICATIONS

Inspection Length: Up to 200km

Inspection Time: 200 Hours

Pipe Coverage: 100%

Capability: ID and OD Wall Loss

Max Tool Speed: Up to 2.0m/s

Max Tool Pressure: 100Bar

Temp Range: 0 to 65 degree

Wall Thickness: 2mm-25mm

Tool Size Available: 3” – 12”

Applications: Onshore and Offshore

UT Technique: Phased Array

Channels: 128 Channels with an aperture up to 32

Sensor Pitch: Configurable to Ring Size

PU Discs or Brushes Available

Data Saving: Raw A Scan

Storage: 8TB or Greater

IMU: Available

Tool Type: Autonomous and Tethered