HOW OUR SENSOR TECHNOLOGY WORKS

Our circular Phased Array ultrasonic sensor technology is transforming pipeline inspection by delivering 360° coverage of the pipe, ensuring 100% detection of defects that conventional methods often miss. Its precision and rapid scanning enhance asset integrity and efficiency while minimising downtime and maintenance costs.

CIRCULAR PHASED ARRAY ULTRASONIC SENSOR

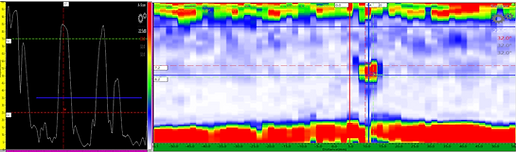

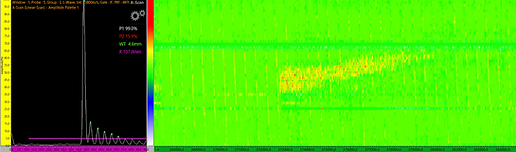

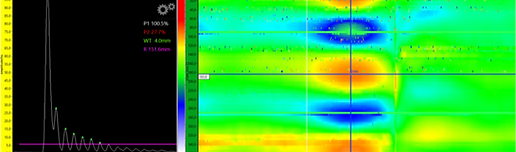

The sensor produces a far more capable and comprehensive ultrasonic beam field than traditional UT probes. Instead of a single fixed-angle beam, the circular array allows us to steer, focus and electronically manipulate the beam in every direction around the pipe wall. This delivers superior crack detection and sharper definition on small corrosion and geometry features.

KEY SENSOR TECHNOLOGY FEATURES

PAUT 360

Circular Array Sensor

Raw UT

A Scan

Data Analysis

A-Scan, B-Scan, C-Scan & D-Scan PAUT Data Set

Shear Wave and Longitudinal Wave Pulsing

Simultaneous

Straight & Multi-Angled Beams

Pulse Echo and Pitch Catch UT Firing

Ultra-High

Resolution Custom Grid Size

Focused

Phased Array Beam Set

100%

Circumferential

Coverage

IMU and AGM Synchronisation with EM tracker

FOUR COMBINED INSPECTION TECHNOLOGIES

PHASED ARRAY UT CRACK DETECTION

Our PAUT sensor is capable of detecting both volumetric and surface-breaking cracks by deploying angled shear wave beams into the pipe wall. These angled beams penetrate the material and reflect off flaws, allowing precise identification of crack location, orientation, and size. By scanning at multiple angles and using high-resolution phased array technology, the sensor can distinguish between different types of defects and provide a comprehensive view of the pipe’s integrity.

PHASED ARRAY UT WALL LOSS

The sensor detects wall loss and corrosion on both the internal (ID) and external (OD) surfaces of pipelines by sending longitudinal wave beams into the pipe wall. These beams penetrate the material to provide precise measurements of wall thickness and identify areas of thinning or material degradation or lamination defects. High-resolution phased array technology allows accurate mapping of wall loss, corrosion extent, and location, distinguishing between uniform and localised defects.

PHASED ARRAY UT GEOMETRY

The PAUT sensor provides the highest resolution inspection capability on the market. It can identify dents, ovality, buckles, and wrinkles in pipelines with high precision. Using advanced phased array scanning, it captures detailed measurements of shape deviations and structural deformations. The results are presented in clear tables and visual maps for easy interpretation. This allows operators to assess pipeline integrity, prioritise corrective actions, and maintain safe and efficient operations.

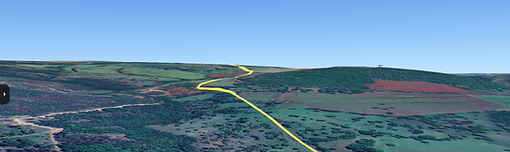

XYZ MAPPING WITH IMU

Our inspection tools are equipped with an onboard Inertial Measurement Unit (IMU), enabling precise XYZ mapping of the pipeline route. This allows the tool to capture the exact GPS location of defects, geometry features, and other critical pipeline attributes. The high-resolution positional data is combined with inspection results to create accurate 3D maps, providing operators with a clear view of defect locations relative to the pipeline’s route. This capability enhances planning, maintenance, and integrity management.

GET A QUOTE FOR OUR

INSPECTION SERVICE