top of page

NEWS & PROJECTS

Keep up to date with our latest news, projects and technology.

Specialists In Phased Array UT Intelligent Pigging.

Using our cutting-edge proprietary inspection technology that delivers high-resolution volumetric inspections with accurate defect sizing and repeatable results. 🔗 Learn More: www.vectorinspection.com

Jan 221 min read

HEATER-PIG™ Is Designed For The Most Challenging Fired Heater And Furnace Tube Configurations.

With 100% coverage of the inspection tubes using the integrated 360 degree Phased Array sensor, the advanced ultrasonic inspection tool provides an unmatched inspection capability improving asset efficiency and performance. Explore Our Inspection Technology: www.vectorinspection.com

Jan 211 min read

Wharf And Loading Lines Are Some Of The Most Difficult Pipelines To Inspect.

With limited access, tight bends, operational constraints, and critical safety implications. We deliver Phased Array intelligent pigging inspections purpose-built for: ⚓ Wharf & jetty loading lines 📐 Tight bends and complex geometry 🌊 Marine pipelines Learn More: www.vectorinspection.com One run. High-resolution integrity data. Confident decisions.

Jan 201 min read

Field-Proven Phased Array PAUT In-Line Inspection Services.

Delivering high-resolution defect sizing and repeatable results, even in challenging and traditionally unpiggable pipelines. Combined ultrasonic inspection capabilities: - Crack Detection - Wall Loss - Geometry - XYZ Mapping Learn More: www.vectorinspection.com

Jan 191 min read

Discover How Our Phased Array (PAUT) Intelligent Pigging Inspection Services Can Detect Internal And External Corrosion In Your Pipelines.

By identifying issues early, you can make necessary repairs before failures occur, ensuring the integrity of your infrastructure. Protect your assets and enhance safety with our latest high-resolution inspection services. Learn More: www.vectorinspection.com

Jan 161 min read

Next-Generation Pipeline Geometry Inspection with PAUT-PIG™

PAUT-PIG™ can identify high resolution geometry defects in your pipelines using advanced Phased Array (PAUT) In-Line inspection technology. Built for complex, small-diameter and unpiggable pipelines. Geometric anomaly detection capabilities include: - Dents - Ovality - Wrinkles - Buckles - Bulges - Misalignments - Diameter Changes Explore Our Inspection Technology: www.vectorinspection.com

Jan 151 min read

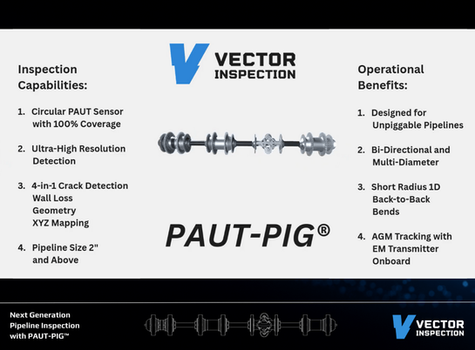

Advanced Pipeline Inspection Solutions with PAUT-PIG™

Pipelines are complex. They often feature changing diameters, low flow conditions, tight plant layouts, and restricted access points. These challenges make traditional larger ultrasonic testing (UT) inspection tools ineffective. The Solution: PAUT-PIG™ That’s where PAUT-PIG™ excels. This innovative technology addresses the unique challenges of pipeline inspection. Key Features of PAUT-PIG™ 🔹 Bi-directional capability – Enjoy full inspection capabilities in either direction

Dec 2, 20251 min read

PAUT-PIG™ - Engineered For The World’s Most Challenging Pipelines

At Vector Inspection, we didn’t design our PAUT-PIG™ for the ordinary and easy to inspect pipelines. We built it specifically for the unpiggable, the complex, the multi-diameter, the tight-radius, the liquid-filled and the operationally demanding pipelines that traditional tools simply can’t handle. By combining advanced PAUT sensor technology with a compact, highly adaptable tool architecture, our PAUT-PIG™ inspection service delivers crack detection, wall-loss measurement,

Nov 28, 20251 min read

bottom of page