top of page

NEWS & PROJECTS

Keep up to date with our latest news, projects and technology.

How The HEATER-PIG™ Is Revolutionising Tube Inspections

For decades, fired heater and furnace tube inspections have been limited by coverage and accuracy. At Vector Inspection, we’ve changed the game. The HEATER-PIG™ is a bi-directional intelligent pigging tool that uses Phased Array Ultrasonics (PAUT) to deliver 100% coverage and 4-in-1 performance inside even the most complex heater coils. The tool is designed to travel through the most complicated systems with 1D bends, Mule-ears and plug headers. ✅ ✅ Crack Detection - Identif

Oct 31, 20251 min read

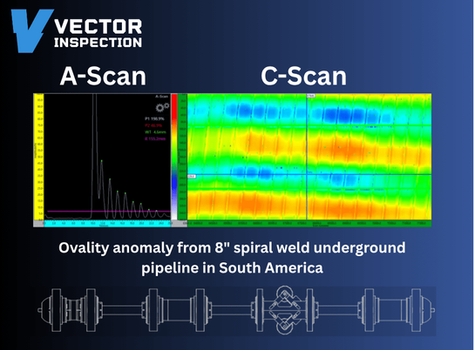

Why The A-SCAN Is Everything In Ultrasonic ILI

In ultrasonic in-line inspection (UT ILI), the A-Scan is the true heartbeat of the data. It’s the raw ultrasonic signal, the untouched waveform that tells the real story of what’s happening inside the pipeline wall. Yet in today’s market, very few inspection providers truly understand or preserve it. Most UT ILI tools on the market either: ❌ ❌ Don’t store the A-Scan data at all ❌ ❌ Heavily downsample it, often losing over 95% of the original data. Unfortunately, if some U

Oct 30, 20251 min read

Why Is In-Line Inspection Critical For Unpiggable Or Challenging Pipelines?

Traditional UT pigging tools often can’t access complex pipeline systems due to their large size, weight and number of pods. That’s where our lightweight and agile intelligent pigging tools make the difference. Utilising 35 years of ultrasonic electronic design experience and the latest ultrasonic chips on the market has enabled us to miniaturise our pigging tools to an unimaginable scale while maintaining a sensor count high enough to achieve 100% internal pipe coverage. Our

Oct 28, 20251 min read

Vector Mobilise For A New Challenging Intelligent Pigging Campaign – Brazil 6”/8” X 6km Ammonia Pipeline

Vector Inspection is mobilising once again in October for a particularly challenging baseline inspection on an ammonia pipeline in Brazil . This pipeline stretches over 6 km and features multi-diameter sections (6"→ 8"→ 6") with tight 1.5D bends . A Significant Milestone This project represents a significant milestone. The line has never been inspected before. This makes it the first baseline UT integrity run . Adding to the complexity, a previous inspection attempt by ano

Oct 24, 20252 min read

Vector Mobilises To South Korea With PAUT-PIG™ For Challenging 4" X 5km Pipeline Inspection

Vector Inspection is proud to announce that in September 2025 we are mobilising to South Korea to deliver a highly challenging pipeline inspection using our advanced PAUT-PIG™ technology . This project represents another step forward in our mission to tackle pipelines once considered unpiggable . We aim to provide operators with the highest-resolution data for safe and efficient asset management. 4-in-1 Technology in Action The inspection will utilise our PAUT-PIG™ 4-in-1 pl

Sep 7, 20252 min read

Vector Invest In New Manufacturing And Testing Facilities

At Vector Inspection, innovation and investment go hand in hand. We are proud to announce the opening of our new manufacturing and testing facility in the North West of England , just 30 minutes from Manchester Airport. With over 10,000 sq. ft of dedicated testing space , this site allows us to rapidly mobilise, replicate real-world inspection conditions, and deliver even greater value to our customers. This facility represents a major investment in our mission to push the b

Sep 7, 20252 min read

Vector Inspection Launches New Website And Brand Identity

We’re excited to announce the launch of our brand-new Vector Inspection website , a fresh digital platform designed to reflect who we are today and where we are heading. This milestone follows hot on the heels of several successful phased array intelligent pigging campaigns delivered around the world, proving the strength of our technology and the value we bring to operators working with challenging and unpiggable pipelines. Our updated brand identity represents more than j

Sep 7, 20252 min read

bottom of page